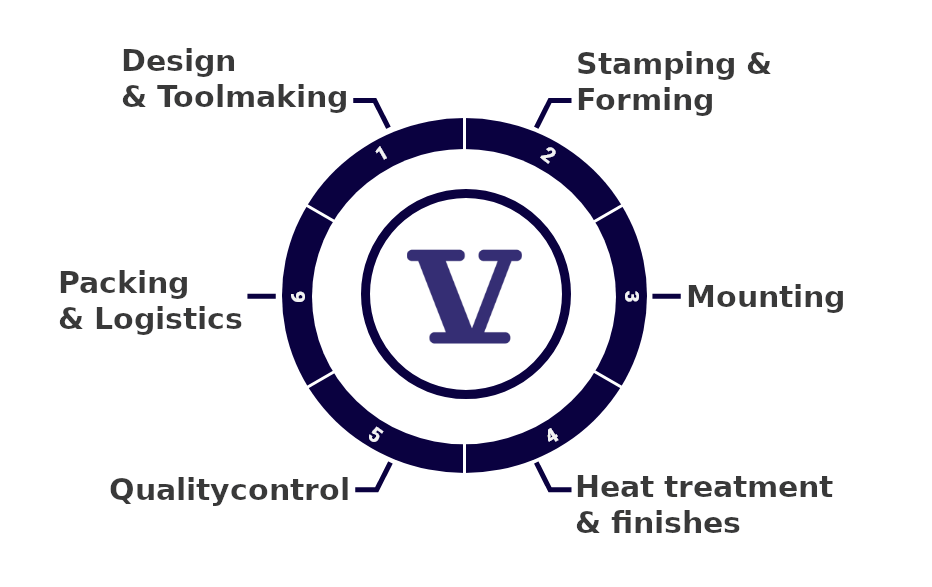

Stamped bent parts

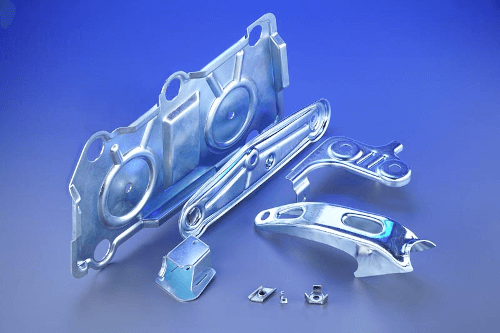

Deep drawn parts

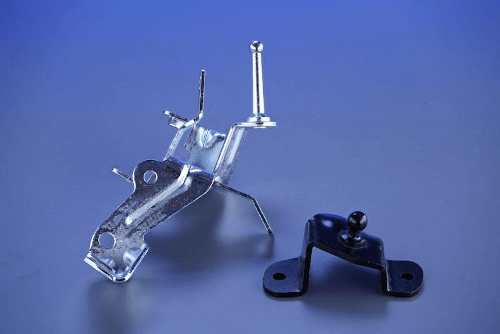

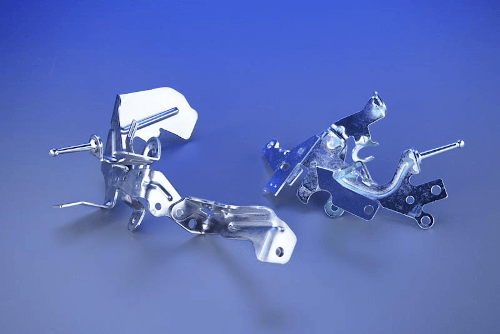

Welded assemblies

Automotive

E-mobility

Commercial vehicles

Agriculture

Construction

Solar technology

Vogelsang...

Quality you can see

Vogelsang...

Quality you can see

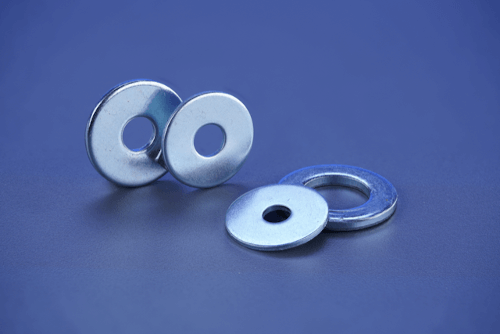

Competence wheel

Design & Development

Manufacturing competencies

VOGELSANG PRODUCTS „MADE IN GERMANY"

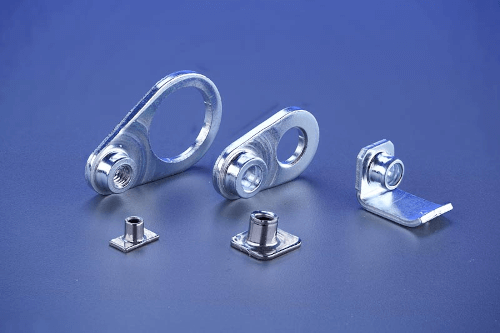

In addition to normal steel, the processing of stainless steel as well as aluminum in our own stamping shop is our specialty. A variety of surface finishes round off our portfolio. Whether nickel, copper plating, chrome plating, salt nitriding, electropolishing or many other finishes: VOGELSANG supplies your stamped parts with a high-quality surface finish as desired.

Stamped and bent parts

Deep drawn parts

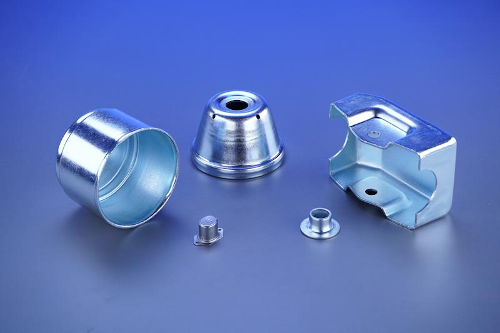

Washers according to DIN/ ISO standards

Stamped parts with drawn threaded tube

Tumble riventing

Welding / Assembly modules

Industries

Over the past decades, many well-known companies have placed their trust in us. They all trust in our experience, the professional handling and the cooperative relationship during the realization of complex projects

Automotive

Electrical / solar technology

Construction / Machinery industry

Agricultural machinery / commercial vehicles

Quality

Even before the introduction of the corresponding standards, quality assurance had the highest priority in our company policy. In 1999, our company was certified for the first time according to DIN ISO 9002: 1994 certified. In the following years, our QM system was converted and certified according to the standards DIN ISO 9001: 2015 and IATF 16949: 2016. The compliance with all customer specifications and thus achieving the classification as "A-supplier" are our ultimate goal. For this purpose the corresponding quality plans are carried out in consultation with the customer and implemented in all areas of product development.

Attributive and variable gauges are available to ensure product quality, as well as standard measuring equipment, profile projector and a 3D measuring arm from FARO. With the measuring equipment used, we are able to reproduce even tight tolerances in a reproducible manner, for example, with a computer-aided measuring system for checking contour, form and position tolerances. Constant adaptation to the changing structures of the market and technology is the prerequisite for the existence of our company.

As a reliable solutions partner, we are therefore continuously developing our products and services. Especially in times of increasingly fierce competition, this attitude will become increasingly important in the future. Supported by national and international partners, we are in a position to react to new market conditions at an early stage and to and to incorporate this knowledge into the customer's new developments. The improvement process driven forward together with customers, employees and suppliers is an important guarantor of our competitiveness.

Environment

Environmental management is an important topic in times of dwindling raw material resources, a changing climate and ever higher energy prices.

In many large and medium-sized companies, especially recently, environmental management has even been declared a top priority. The environmental policy of Ernst Vogelsang GmbH is primarily intended to promote the self-awareness of our employees for our environment. Our claim is to protect the environment sustainably and to take into account economic and ecological concerns.

In all our activities, we therefore attach the greatest importance to the best possible use of resources and careful treatment of the environment. Ever newer, stricter and more complex environmental protection requirements and environmental protection laws have led to our certification in 2012 according to the international standard DIN EN ISO 14001:2015.